TUBE+ PROCEDURE

Partial tube thickening in the cold forming process using the Tube+ method

Get to know the versatile and resource-efficient cold forming process in action.

The Tube+ process in detail

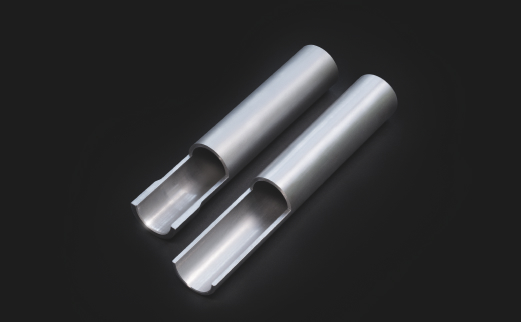

The Tube+ process developed by Felss enables partial tube thickening in the cold forming process for the first time. The process is used in the production of preliminary stages, which contribute to simplifying the process chain in subsequent steps. It is a supplement or alternative to rotary kneading.

How does pipe thickening work?

With Tube+ technology, partial outward thickening of components is possible. The components are formed by controlled upsetting, whereby the workpiece is completely enclosed by reinforcement to avoid the risk of upsetting. The unmachined part is simultaneously calibrated to a very low tolerance by the process, making the tube more precise.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Tube+ applications

The Tube+ technology offers various advantages and applications and represents a supplement or alternative to rotary swaging – several process steps can be saved and the processing time shortened. Possible applications include process expansion or the targeted thickening of thin-walled pipes.

Advantages of the Tube+ procedure

- Low material and component costs.

- Savings in process steps with short process times.

- Very high diameter and concentricity.

- High solidification of the material.

Added value with Felss Technology

Felss stands for smart, customized solutions in cold forming. Our aim is to offer you real added value with our machines, components and services.

- Optimized material distribution: achieving weight reduction without compromising strength

- Enhanced mechanical properties: work hardening and improved fatigue strength through cold forming

- Resource efficiency: near-net-shape forming minimizes material waste

- Stable and efficient production: reduced machining, fewer process steps, and shorter lead times

- High precision for complex geometries: achieved through synchronized machine control and advanced tooling concepts

- Customized solutions: in-house process development, tooling design, and machine configuration tailored to your specific requirements

Tube+ machine

Reduction of process steps through pipe thickening.

Come to us as early as the development phase of your projects

We support you throughout the entire process – from the drawing to the finished component and beyond.