Rollers

Nicolas Heck

All about rolling: basics, processes and applications

According to DIN 8582, rolling is one of the basic processes in solid forming and is a non-cutting production process for mostly metallic materials. The material is formed and its cross-section reduced by pressure forming between two or more rotating rolling mills. To do this, the workpiece is fed through the rollers under pressure. The geometric design of the rollers and the level of compressive stress determine the degree of forming and the shape of the end product.

Rolling – The non-cutting manufacturing process

This means that only a – relatively small – part of the workpiece is directly stressed by the forming process. This is due to the radial shape of the tools. The contact surface between the workpiece and the roller is rather small due to the cylindrical roller shape, which means that the pressure is localized and effectively transferred to the material. If the workpiece is also heated beforehand, the force required for rolling continues to decrease. In this case, we speak of hot rolling or hot forming, or cold rolling or cold forming if the material is rolled without the prior application of heat.

State-of-the-art rolling technology from Felss: HMP Rolling

At Felss, we know how important state-of-the-art rolling technology is for your success. Our expertise and our customized rolling systems are your solution for first-class results. Whether you need Wire Reduction Rolling Mills, Flat and Profiled Wire Rolling Mills, Ultra-Precision Rolling Mills, Strip Rolling Mills or Cross Profile Rolling Mills – Felss stands for quality and reliability. Rely on us to take your rolling processes to the next level.

Basics of the rolling process

The rolling process is a complex procedure that begins with cleaning and pre-treatment to reduce surface impurities. The material is then passed between two or more rotating rollers, i.e. heavy cylindrical drums. These rotate in opposite directions and exert pressure on the material, deforming it and stretching its length. This process requires push and pull forces to pull the workpiece through the rollers. Alternatively, the friction can also be sufficiently high to ensure that it is pulled in automatically. If a high rolling pressure is required, several pairs of rollers are used. This is the case, for example, with hard materials such as high-strength steels or for a significant reduction in material pressures.

Exact dimensions and material properties

This means that only a – relatively small – part of the workpiece is directly stressed by the forming process. This is due to the radial shape of the tools. The contact surface between the workpiece and the roller is rather small due to the cylindrical roller shape, which means that the pressure is localized and effectively transferred to the material. If the workpiece is also heated beforehand, the force required for rolling continues to decrease. In this case, we speak of hot rolling or hot forming, or cold rolling or cold forming if the material is rolled without the prior application of heat.

Which technical parameters are important for rolling?

In the field of metal processing, rolling is a crucial process that significantly determines the shape and properties of metal products. This complex process requires precise coordination of several key factors in order to achieve the desired quality and accuracy.

Roll pressure and roll gap

Roller pressure is a key factor. It significantly influences the deformation of the material and is decisive for the thickness and mechanical properties of the rolled product. In modern roll stands, which can contain up to twelve rollers, the work rollers in direct contact with the material play a key role, while downstream auxiliary rollers take on supporting functions. The roller gap, i.e. the distance between the rollers, is also crucial as it determines the final thickness of the workpiece. Precise control of this distance is therefore essential in order to achieve the desired dimensions of the end product.

Temperature control

Temperature control is essential to ensure that the material is sufficiently malleable without undesirable stresses or structural changes. This is particularly important when complex shapes or precision profiles need to be created and applies to all rolling processes, regardless of their specific application.

The hardness of the material

The hardness of the material to be rolled also plays an important role, as it influences how the material reacts to the rolling process. This in turn affects the setting of other parameters such as pressure and rolling speed in order to achieve optimum results.

What are the advantages of cold rolling compared to hot rolling?

Hot rolling and cold rolling are two central processes in metal processing that are selected depending on the requirements of the end product. Hot rolling processes metal at temperatures above 1100 degrees Celsius, making it ideal for the mass production of long steel products. However, this method produces a coarser surface and less precise profiles. In contrast, cold rolling takes place at room temperature or below the recrystallization temperature of the material. This allows high-precision and fine surfaces to be produced and exact dimensional tolerances to be achieved. In addition, the microstructure of the material changes during the rolling process as a result of work hardening, which leads to increased tensile strength.

Cold rolling: energy-efficient and precise

Both techniques can be used for different grades of stainless steel, although it should be noted that some can change their properties when heated and a change in shape can occur after cooling. In addition, significantly more energy is required for hot rolling. While hot rolling is usually used when large shape changes are required – which is particularly the case for initial rough forming – cold rolling is the preferred process when high dimensional accuracy, fine adjustment and improved surface quality are required. This process is often used for fine machining.

What types of rollers are there and how do they work?

There are various processes, each of which has been developed for specific requirements in metal processing. Each method has its own strengths and specializations: While some focus on the production of flat or profiled metal products, others are ideal for the production of precise, fine structures. Below we will look at some of these processes and rolling lines in more detail, including techniques that specialize in the production of metal strips, seamless tubes and precision rings, as well as those that are essential for the production of fine and precision wires.

Strip Rolling Mills

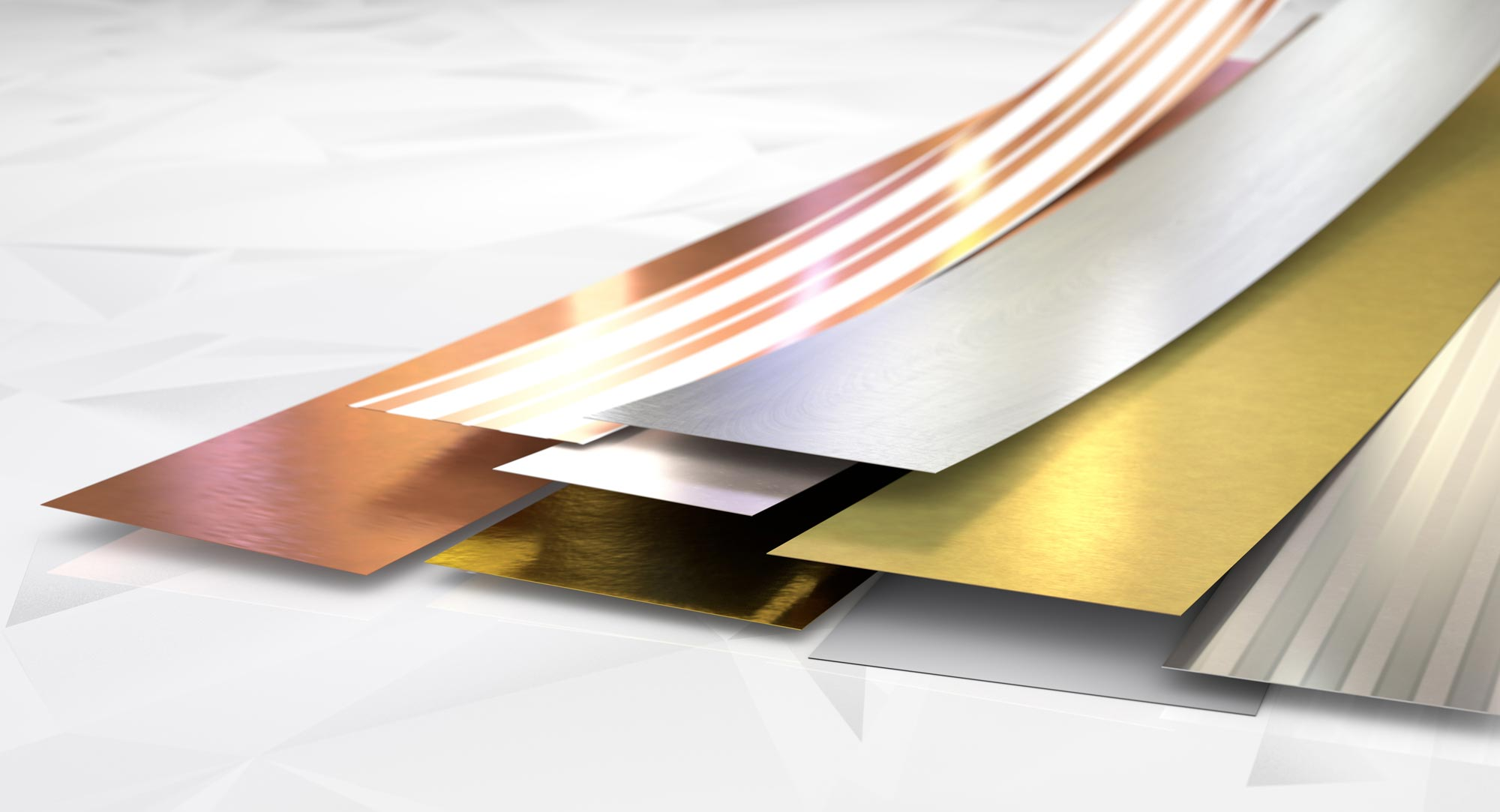

Strip Rolling Mills is a metal processing method that aims to roll metal strips or coils into specific thicknesses and widths. This process is often used to manufacture thin, flat metal products that are used in various industries. This technology uses different roller configurations, including Duo Strip Rolling, which is suitable for processing thicker strip thicknesses, and Quarto Strip Rolling, which is used for the finest strip thicknesses with low tolerances. The precision and efficiency of the strip rolling process depend on the precise control of various parameters such as roll adjustment and rolling force.

Tube rollers for tube production

Tube rolling is a mechanical process in metal processing in which tubes are bent and shaped. The tube material is fed through a specialized rolling machine to produce the desired bend, shape or geometry. This process can be used in various industries, including the production of seamless pipes for power generation, pipeline construction, the automotive industry and much more. Tube rolling enables the production of tubes with precise bends and shapes, which is crucial in many applications.

Ring rollers

Ring rolling is a process for producing seamless rings from metal. A smaller metal ring is continuously stretched and formed between rollers to produce a ring of larger dimensions. This requires two separate roll gaps: One for the ring wall thickness and one for the ring height. A radial roll gap is used to change the thickness of the ring between a main roll and a mandrel roll, while in the axial roll gap the height of the ring is adjusted by two conical rolls. This process increases the diameter of the ring. The machine can also be used to produce specially profiled rings by using appropriately shaped rollers. This technology enables the production of rings with high precision dimensions and is crucial for applications where the quality and accuracy of the ring geometry are critical.

Flat and profile rollers

Flat rolling is versatile and enables the manufacture of products in a wide range of thicknesses, from solid sheets to fine foils. Profile rolling, on the other hand, uses calibers to produce a wide range of profiles. These calibers, which determine the shape of the roller engravings, vary from simple shapes such as round or square to more complex profiles such as beams or rails. Calibers can also be classified according to their function, including welding calibers, developing calibers and finish rolling calibers to produce specific profile types and sizes.

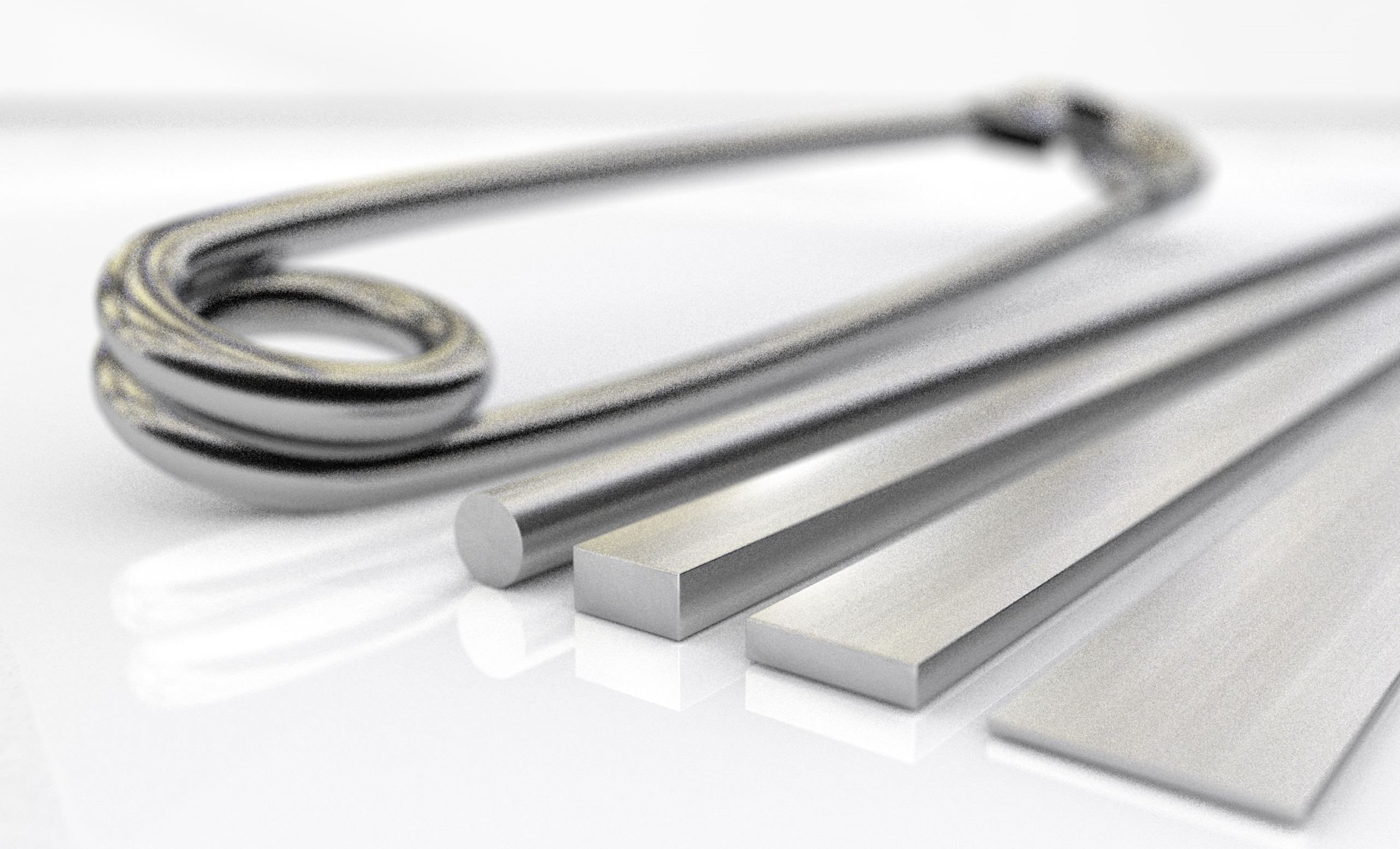

Ultra-Precision Rolling Mills

Ultra-Precision Rolling Mills is an advanced metal processing method that is characterized by extreme accuracy. It is used, for example, to roll round wires with small diameters into various shapes and profiles with precise dimensions. The process is characterized by high-precision and dynamic rolling adjustments that enable tolerances in the nanometer range. Ultra-Precision Rolling Mills are used in the production of the finest wires required in areas such as electronics and medical technology. This process uses state-of-the-art machine technology and makes it possible to produce extremely fine and precise products of high quality.

Wire Reduction Rolling Mills

Wire Reduction Rolling Mills are used when the cross-section of wires needs to be reduced. Alternating processing by rolling rings as a cold rolling process not only makes the wire thinner, but also stronger and harder. The wire passes through several pairs of rollers, where it is alternately processed horizontally and vertically by profiled rolling rings. Various geometries and profile shapes can be created, such as round, oval or rectangular, with any number of corners. The technology is characterized by its ability to achieve high cross-section reductions and produce precise profiles. The roll stands are designed to be robust and torsion-resistant to ensure the precision and efficiency of the process.

Briefly summarized: Rollers

Rolling is an essential process in metal processing that reduces the thickness of a material and gives it a specific shape through pressure forming between rotating rolling mills. This non-cutting manufacturing process enables the production of a wide range of products and requires precise coordination of various parameters such as roll pressure, roll gap and temperature control.

Questions about rolling?

Do you have questions about our products and services and would like to find out more about Felss? Then do not hesitate to contact us! Our experts will be happy to advise you.

Come to us as early as the development phase of your projects

We support you throughout the entire process – from the drawing to the finished component and beyond.