ROTARY SWAGING

Efficient cold forming of lightweight and high-performance components

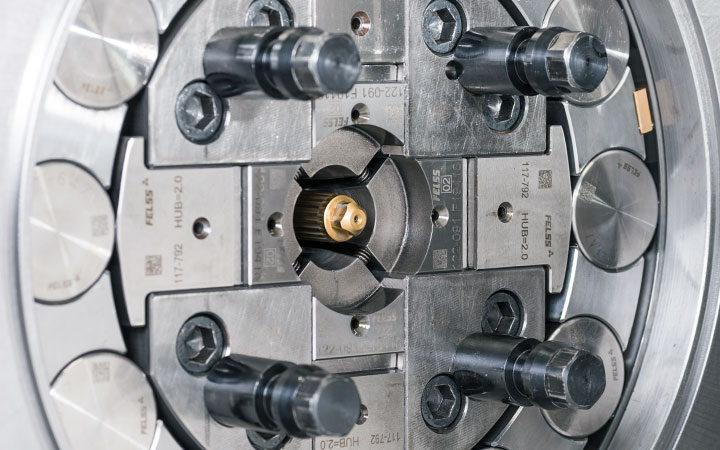

Rotary swaging is a high-precision cold-forming process in which several die segments oscillate radially and simultaneously strike the workpiece in rapid succession. These repeated, incremental forming steps cause the material to flow in a controlled manner, enabling the production of dimensionally accurate components with tailored mechanical properties. The process accommodates a wide range of external and internal geometries and offers considerable design freedom for both visible and structural parts.

The Felss Group – Specialists in Rotary Swaging

With decades of expertise in rotary swaging and axial forming, the Felss Group provides machine systems capable of producing complex cold-formed components to extremely tight tolerances. Our modular machine platforms allow the forming of demanding workpieces with high reproducibility and process stability. Additionally, our contract manufacturing services give you access to our full process know-how and advanced machinery — from prototype development to series production.

Process Principle

In rotary swaging, multiple die segments strike the workpiece at frequencies exceeding 1,000 strokes per minute. Each stroke produces a small, incremental forming step of typically 0.25 to 1.5 mm. This incremental forming approach reduces forming forces, ensures excellent formability, and promotes homogeneous material flow. During the process, the workpiece undergoes cold working, leading to an increase in strength and fatigue resistance.

The process can be performed with stationary or rotating workpieces, and with or without internal mandrels, depending on the required geometry.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Application Range

Rotary swaging covers a broad forming spectrum, extending far beyond conventional cold-forming methods. Typical applications include:

- Tubular and solid shafts (e.g., steering spindles, drive shafts)

- Energy absorption components (e.g., airbag tubes)

- Precision adjustment mechanisms

- Hose connections and fittings

- Lightweight structural components requiring tailored outer or inner contours

Thanks to its incremental, low-force forming mechanism, even thin-walled tubes and high-strength materials can be processed reliably, as long as the material exhibits sufficient formability.

Process Advantages

- Programmable kinematics: freely adjustable stroke frequencies, feed rates, and forming profiles

- High geometric flexibility: suitable for stepped, tapered, polygonal, or spline-like geometries

- Short cycle times: high stroke rates and minimal workpiece handling

- Low tooling effort: reduced number of change parts and short setup times

- Excellent repeatability: inherently stable process with low tolerance variation

Added value with Felss Technology

Felss stands for smart, customized solutions in cold forming. Our aim is to offer you real added value with our machines, components and services.

- Optimized material distribution: achieving weight reduction without compromising strength

- Enhanced mechanical properties: work hardening and improved fatigue strength through cold forming

- Resource efficiency: near-net-shape forming minimizes material waste

- Stable and efficient production: reduced machining, fewer process steps, and shorter lead times

- High precision for complex geometries: achieved through synchronized machine control and advanced tooling concepts

- Customized solutions: in-house process development, tooling design, and machine configuration tailored to your specific requirements

Generation e4.0

Energy-saving rotary swaging.

Rotary swaging machines HA

Reshape and return at the same time.

Rotary swaging machines FR

Simplest operation.

Complex Geometry Capabilities

The small incremental forming strokes allow the realization of complex external contours with high dimensional accuracy. When an internal mandrel is used, internal splines, tapers, and other intricate inner geometries can be produced — often eliminating subsequent machining operations. Even multi-stage forming sequences can be integrated into a single process cycle.

Lightweight Engineering through Rotary Swaging

Cold-forming via rotary swaging can increase fatigue strength by up to 30%, enabling significant downsizing of cross-sections. Hollow shafts and lightweight structures can therefore be produced with weight reductions of up to 50% compared to conventional machining. This results in key advantages for the automotive sector, such as:

- Improved energy efficiency in combustion-engine vehicles

- Increased range in electric vehicles

- Reduced mass in industrial machinery and rotating equipment

Come to us as early as the development phase of your projects

We support you throughout the entire process – from the drawing to the finished component and beyond.